The Evolution of Composites

In the world of materials science, composites have revolutionized numerous industries, from aerospace to sporting goods. Composites, essentially materials made from two or more materials with significantly different physical or chemical properties, offer enhanced strength, durability, and versatility compared to traditional metals. Among these advanced materials, G10 composite stands out for its remarkable properties, making it an excellent choice for tactical blades and tools. This article delves into what G10 is, how it works, and why it’s an exceptional material for tactical and self-defense blades.

What is G10?

G10 is a high-pressure fiberglass laminate, a type of composite material made from layers of fiberglass cloth soaked in epoxy resin, then compressed and baked. The result is a material that is extremely strong, lightweight, and resistant to moisture, chemicals, and extreme temperatures. These properties, combined with a lack of metallic components in the blade, make G10 ideal for the realm of tactical and self-defense tools, especially in scenarios where concealment is of the utmost importance.

G10 is composed primarily of fiberglass and epoxy resin. The fiberglass provides the foundational strength and durability, while the epoxy resin binds the fiberglass layers together, adding to the material’s overall rigidity and chemical resistance. The key properties of G10 include high strength, lightweight nature, durability, and non-conductivity. Its layered construction makes it incredibly strong and able to withstand significant forces without breaking or deforming. Despite its strength, G10 is much lighter than metals, making it ideal for applications where weight is a critical factor. It is highly resistant to wear and tear, as well as environmental factors like moisture and chemicals, ensuring a long service life. Unlike metals, G10 is non-conductive, making it safer to handle in various environments.

The manufacturing process of G10 involves layering sheets of fiberglass cloth, saturating them with epoxy resin, and subjecting the assembly to high pressure and heat. This process creates a dense, solid laminate that retains the strength of fiberglass and the resilience of epoxy. The high-pressure process ensures that the layers are tightly bonded, preventing the layers from coming apart and maintaining structural integrity even under stress.

Comparing G10 to Carbon Fiber and Traditional Metals

G10 offers several advantages over both carbon fiber and traditional metals. When compared to carbon fiber, both materials offer high strength, but G10 has a slight edge in impact resistance. While carbon fiber is exceptionally strong in tension, it can be more brittle under sudden impacts compared to G10. Carbon fiber is lighter than G10, making it a preferred choice in applications where every gram counts, though the weight difference is minimal in most tactical blade applications. Additionally, G10 is generally more cost-effective than carbon fiber, making it accessible for a wider range of products without compromising on performance. G10 is also more resistant to environmental factors like moisture and chemicals, while carbon fiber can degrade when exposed to certain chemicals.

When compared to traditional metals, G10 offers a higher strength-to-weight ratio, providing immense durability with significantly less material weight. Unlike metals, G10 does not rust or corrode and it requires less maintenance than metals, which often need regular cleaning and protection against corrosion. G10’s combination of strength, durability, and versatility make it uniquely suited for tactical blades because it can be manufactured to very precise specifications, ensuring consistent quality and performance. Its resistance to environmental factors means that G10 knives can be relied upon in a wide range of conditions, from humid jungles to arid deserts. G10’s non-conductive properties also make it safe to use in environments where electrical hazards might be a concern. Additionally, its lightweight nature makes it ideal for everyday carry (EDC) applications, where weight and comfort are crucial.

G10 Blades and Concealment

One of the standout features of G10 blades is their ability to be concealed easily. The material allows for the production of very thin, lightweight blades that do not add unnecessary bulk. This is particularly important for self-defense tools, where discretion and surprise can be key advantages. Furthermore, the lack of metal components allows G10 to be unnoticed by basic metal detectors, enhancing your concealment when required.

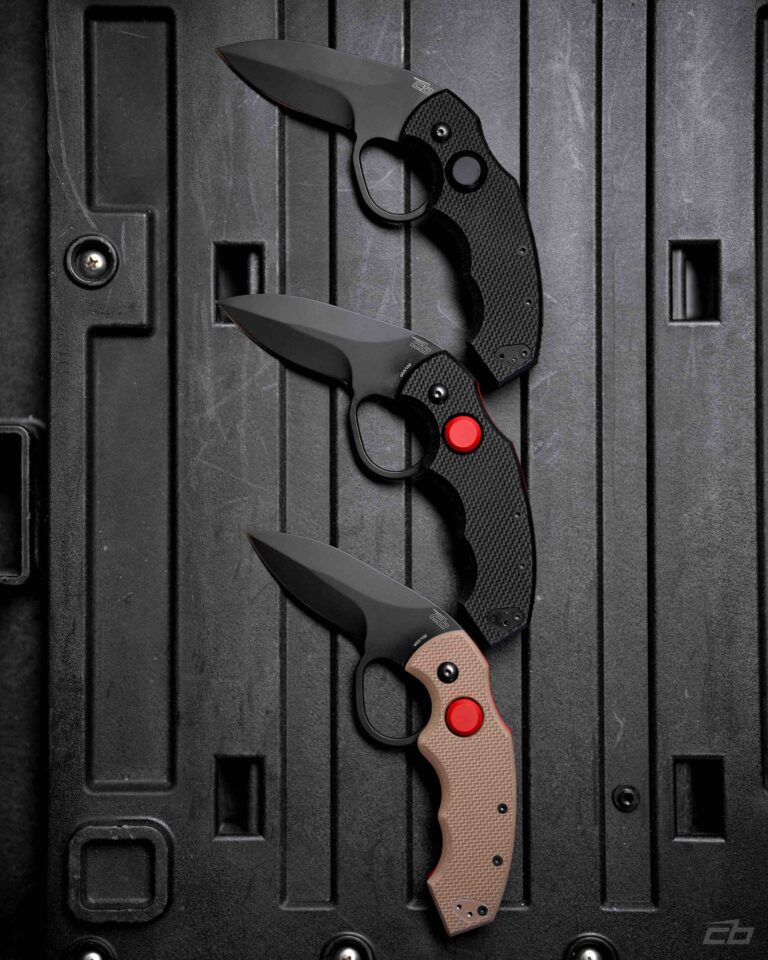

The NCO G10 Knife: Designed for Maximum Concealment

At Colonel Blades®, our NCO G10 knife embodies the pinnacle of what G10 can offer. The NCO G10 is designed to be incredibly thin, ensuring maximal concealment without sacrificing strength or functionality. Its lack of an added grip surface enhances its slim profile while the ring and blade design make the grip feel natural and easy. The NCO G10’s blade is robust enough to handle the demands of tactical use while remaining virtually undetectable when carried. This makes it an ideal choice for law enforcement professionals and everyday consumers looking for a reliable self-defense tool.

Maintenance Tips for G10 Blades

Maintaining a G10 blade is straightforward, given the material’s inherent durability. To ensure your G10 knife remains in top condition, it’s essential to clean the blade with a damp cloth to remove any debris or residue. For more thorough cleaning, use mild soap and water, but avoid soaking the knife. Sharpening the blade with a sharpening stone or professional sharpening service maintains the blade’s edge, ensuring optimal performance. While G10 handles do not require much maintenance, keeping the blade sharp is crucial. Storing the knife in a dry place prevents any potential moisture buildup, even though G10 is moisture resistant.

G10 composite represents a significant advancement in material technology, particularly for tactical and self-defense applications. Its strength, durability, and lightweight properties make it an ideal choice for high-performance knives. At Colonel Blades®, our NCO G10 knife showcases these advantages, providing a discreet yet powerful tool for law enforcement and everyday consumers alike. To learn more about the NCO G10 and see how it can enhance your self-defense capabilities, visit our product page. Experience the strength and reliability of G10 for yourself.